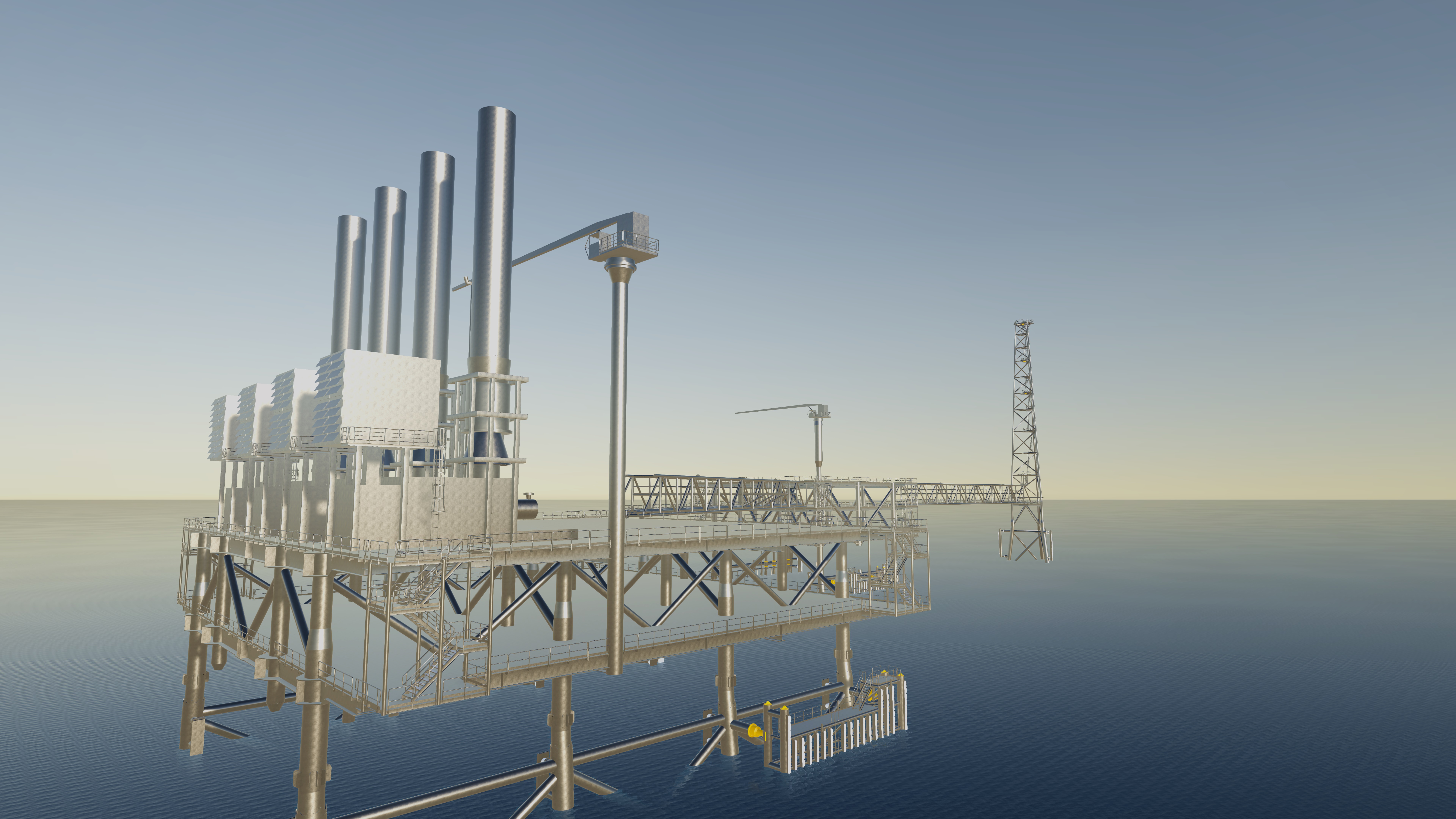

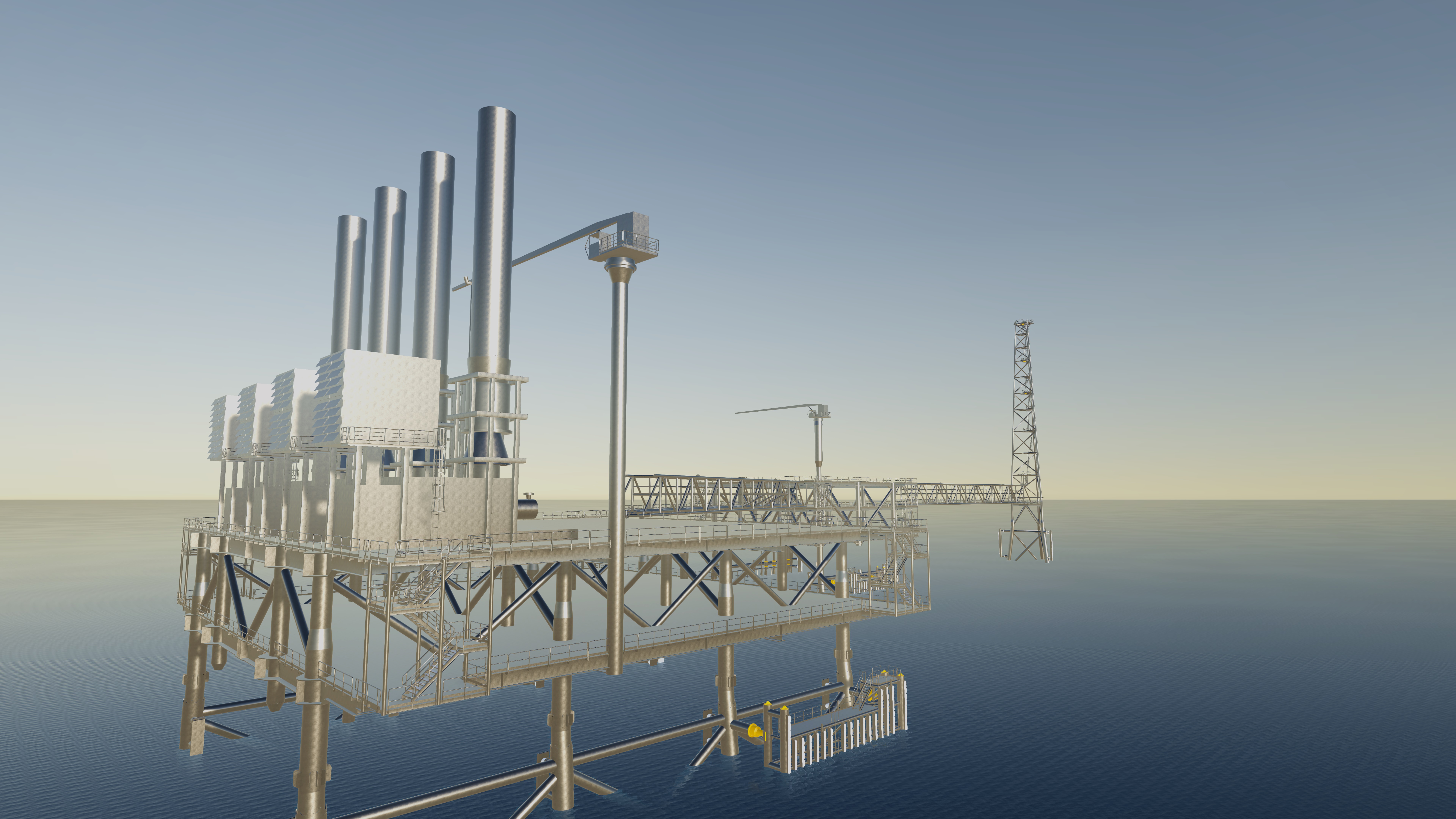

Concept and Basic Engineering for Green Field Compression Hub Middle East

Confidential

Portfolio

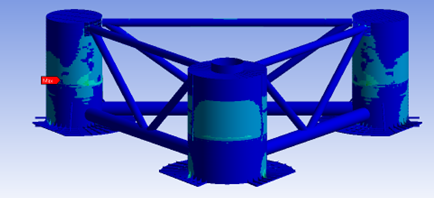

A selection of structural engineering scopes delivered across offshore wind and oil & energy sectors.

Portfolio

Confidential

Principle Power

Principle Power

Dogger Bank Wind Farm

Confidential

KCI The Engineers

Seagreen Wind Energy